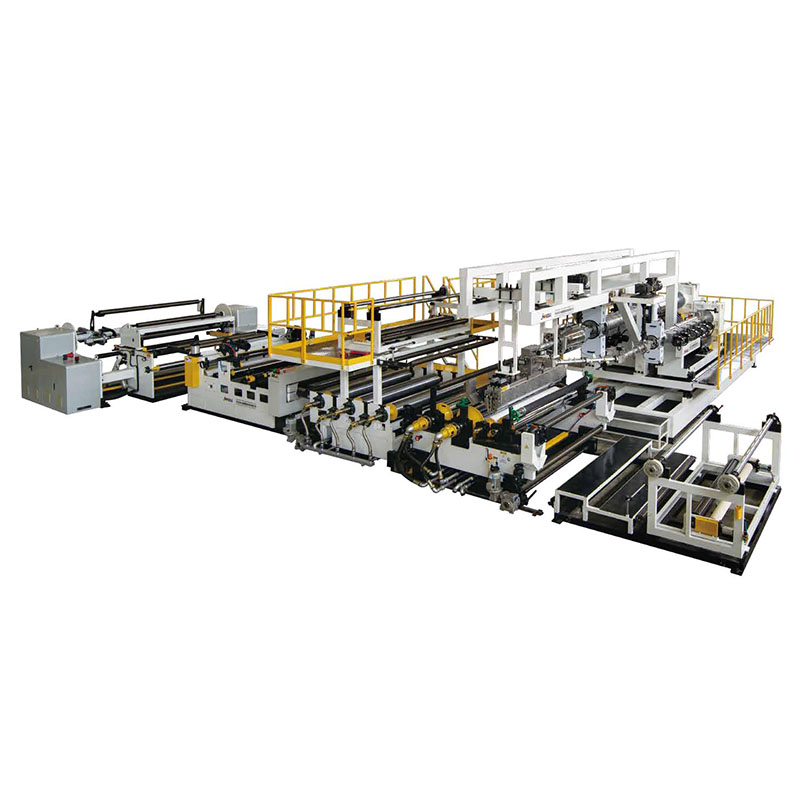

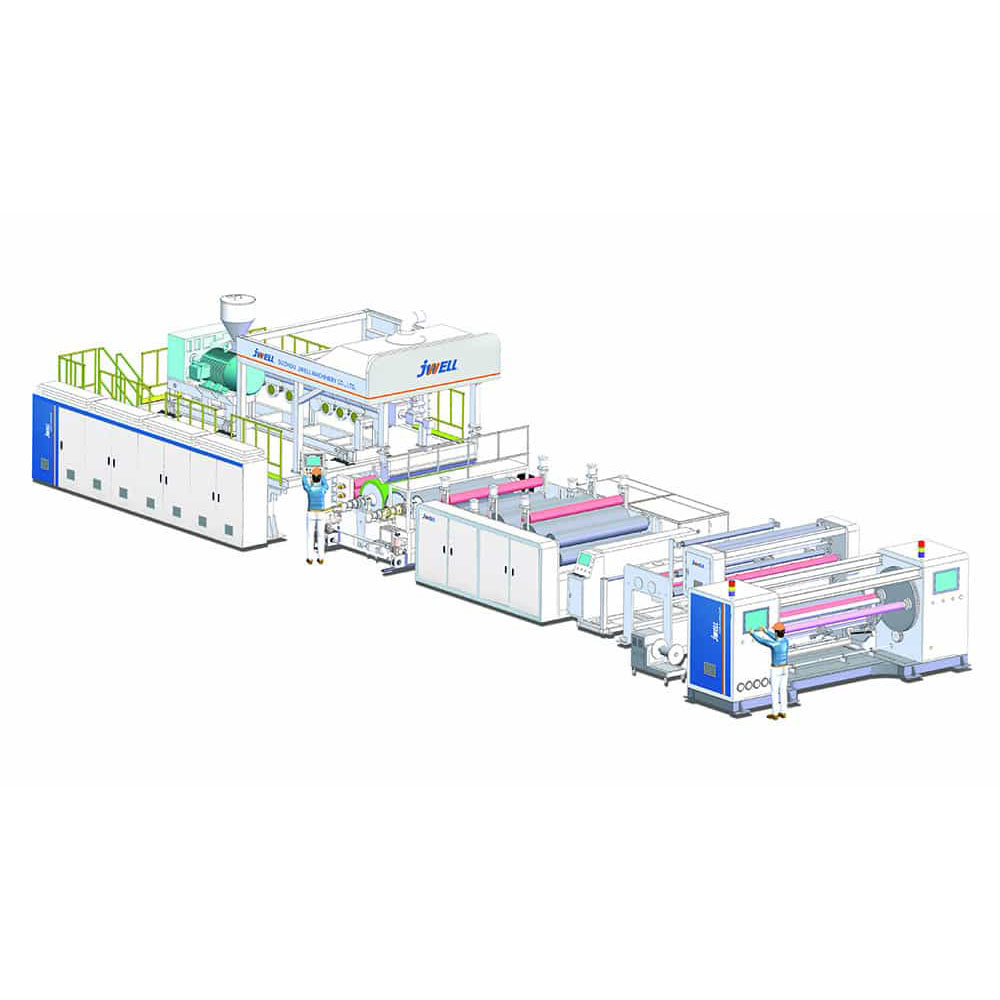

TPU Film Extrusion Line

TPU film is formed by the extrusion of TPU particles through the TPU film extrusion line. There are mainly four processing methods: blow molding, casting, calendering or calendering sheet forming, and extrusion coating. For example, extrusion casting is TPU. The pellets are melted and plasticized by the extruder, extruded from the die head through the slit die so that the molten material is close to the cooling roller, and then the finished product is obtained by peeling, stretching, slitting, and rolling.

Principle of TPU film extrusion line

The raw material enters the barrel from the hopper. Under the action of the screw rotation of the TPU film extrusion line, it is forwarded to the feeding section through the frictional shearing action of the inner wall of the barrel and the surface of the screw, where the loose solid is transported forward and compacted; in the compression section, the depth of the screw groove becomes shallower, and it is further compacted. At the same time, with the heating outside the barrel and the friction and shearing effect of the screw and the inner wall of the barrel, the material temperature rises and begins to melt, and the compression section ends; the homogenization section makes the material uniform, constant temperature, quantitative, The melt is extruded at constant pressure and is formed after reaching the die, and the product is obtained after setting.

TPU film extrusion line can use one or more single-screw extruders to co-extrude TPU, and each extruder is divided into 8 temperature control zones for accurate temperature control. It can meet the need to release the film for the upper and lower layers at the same time, with cloth attached, and PLC overall control is adopted. It can be easily controlled by only one person. The key components are easy to disassemble and replace, humanized, and remote control ports are reserved. high.

TPU film extrusion line composition

As a TPU film extrusion line supplier, China JWELL extrusion molding equipment consists of an extruder, die and die, auxiliary machine, and so on. The main engine of the plastic extruder is the extruder, which consists of an extrusion system, a transmission system, and a heating and cooling system.

Extrusion system

The tpu film extrusion line extrusion system includes a screw, a barrel, a hopper, a head, and a die. The plastic is plasticized into a uniform melt through the extrusion system, and under the pressure established in this process, it is continuously extruded by the screw. Get out of the plane.

1. Screw: It is the most important part of the extruder, which is directly related to the application range and productivity of the extruder. It is made of high-strength and corrosion-resistant alloy steel.

2. Barrel: It is a metal cylinder, generally made of alloy steel with heat resistance, high compressive strength, strong wear resistance and corrosion resistance or composite steel pipe lined with alloy steel. The barrel cooperates with the screw to realize the pulverization, softening, melting, plasticizing, exhausting and compacting of the plastic, and continuously and uniformly convey the rubber material to the molding system.

3. Hopper: The bottom of the hopper is equipped with a cutting device to adjust and cut off the material flow, and the side of the hopper is equipped with a sight hole and a calibration metering device.

4. The machine head and mould: The head of the tpu film extrusion line is composed of an inner sleeve of alloy steel and an outer sleeve of carbon steel, and a forming mould is installed in the head. The function of the machine head is to convert the rotating plastic melt into parallel linear motion, evenly and smoothly introduce it into the mold sleeve, and give the plastic the necessary molding pressure.

Transmission system

The function of the transmission system is to drive the screw and supply the torque and speed required by the screw during the extrusion process, which is usually composed of a motor, a reducer and a bearing.

Heating and cooling device

Now China's TPU film extrusion line usually uses electric heating, which is divided into resistance heating and induction heating. The heating film is installed in the body, neck and head of the machine. The heating device heats the plastic in the cylinder externally to heat it up to the temperature required for the process operation.

The cooling device is set up to ensure that the plastic is in the temperature range required by the process. Specifically, it is to remove the excess heat generated by the shear friction of the screw rotation, so as to avoid the plastic decomposition, scorch or difficulty in shaping due to excessive temperature.

TPU Film Extrusion Line Product Advantages

Due to its good elasticity, good physical properties, and good mechanical strength, TPU film is widely used in processing methods such as dry spraying, extrusion, transformation and dissolution into solution resins. It is a commonly used plastic material in the plastics processing industry. Its products Cover my range of applications and civilian necessities.

JWELL as a China Plastic Extruder manufacturer, there are two trends in the use of TPU film in sport's shoes: one is a popular trend caused by women's sandals, that is, high-transparency tou pieces or direct cutting, or printing on the screen, or the The base of the fabric is put into the mesh, etc. The second is to use waterproof and permeable TPU membrane and shoe cloth together to achieve the effect of waterproof and permeable.

Compared with PVC, EVA, butyl rubber and other plastic materials, TPU not only has excellent properties such as environmental protection, non-toxicity, mildew resistance, corrosion resistance, biocompatibility, etc. Aging, good weather resistance and other excellent properties. In the 20th century, it will become one of the mainstream environmental protection materials because of its incomparable advantages.

TPU Film Extrusion Line, Hot Melt Film Extrusion Line Main Technical Parameter

The TPU Film Extrusion Line adopts high-speed extrusion calendering and casting. The product quality is excellent and controllable. The thickness of the product is 0.01-2.0 mm, and the width is 1000-3000 mm. It is suitable for TPU film products with transparent color, frosting, fog surface, and multilayer composite.

| Model | Products width(mm) | Products Thickness(mm) | Capacity(kg/h) |

| JWS120/36 | 1000-3000 | 0.02-2.0 | 200-300 |

| JWS130/36 | 1000-3000 | 0.02-2.0 | 300-400 |

| JWS150/36 | 1000-3000 | 0.02-2.0 | 400-500 |

TPU Film Extrusion Line Application

TPU material is thermoplastic polyurethane, which can be divided into polyester and polyether. TPU film has excellent characteristics of high tension, high elasticity, high wear resistance, and aging resistance, and has the excellent characteristics of environmental protection, non-toxic, mildew proof and antibacterial, biocompatibility, etc.

It is widely used in shoes, clothing, inflatable toys, water and underwater sports equipment, medical equipment, fitness equipment, car seat materials, umbrellas, bags, and packaging materials, and can also be used in optical and military fields.

TPU film extrusion line product application.

Shoe material

TPU shoes are the main reason for their excellent softness and damage. In terms of wearing comfort, TPU shoes are much better than ordinary shoes. Therefore, they are more and more widely used in high-grade footwear products, especially some sports shoes. casual shoes.

Film

TPU film extrusion line film products are more and more recognized by consumers because of their superior environmental performance. According to the current trend, TPU material can be used wherever PVC material can be used, but TPU material can be used. It is not necessarily applicable to PVC material, which is one of the manifestations of the superiority of this material.

Adhesive

TPU adhesive is a kind of dry polyurethane adhesive. The use of polyurethane adhesives in Europe and the United States has always been appropriate, especially in the use of shoe adhesives, it is only the use of polyurethane adhesives.

Hose

The TPU hose produced by TPU film extrusion line has excellent tensile strength, impact strength, and high and low-temperature resistance, it is widely used in gas transmission aircraft, tanks, automobiles, motorcycles, machines tools and in our TPU hoses and other mechanical equipment, oil hose.

Wire

TPU material has the characteristics of tear resistance, etc., and these properties are required by the cable and wire industry, so TPU film can also be used to maintain wires and cables.

As a supplier of TPU film extrusion line, Jwell machine has devoted a lot of enthusiasm and enthusiasm to the field of Film Extrusion Line. Jwell extrusion machinery group has always been customer-centric, creating concepts for customers, winning the market with quality and service, and sincerely hope that Can cooperate with all walks of life to create success and brilliance together.

FAQ

● International Commercial Terms(Incoterms): FOB, CFR, CIF, EXW.

● Terms of Payment: LC, T/T.

● Average Lead Time: Peak season lead time: 3-6 months, Off season lead time: 1-3 months.

● Number of Foreign Trading Staff:>50 People.

Yes, We own 5 manufacturing bases and sales center in Shanghai, Suzhou, Changzhou, Zhou Shan, Dongguan China.

Jwell made the first Chinese screw and barrel in 1978 in brand name Jinhailuo. After more than 40 years development.

JWELL is one of the biggest extrusion machine supplier in China with 300design&test engineer, 3000 employees.

Jwell has become the premier supplier of extrusion lines and reliable business partners. Welcome to drop in us.

Our machines taking the European standards and follow the Germany type of business, we cooperation with International famous brands Siemens Schneider Flender Omron ABB WEG Falk Fuji etc. Our company continuously imports over 1000 international first-class high precision processing equipment such as multistage machining centers, CNC lathes and CNC milling machines from Korea, Japan etc. All our processes strictly adhere to CE certification, IS09001 and 2008 quality management system. And we have 12 months quality warranty time. We testing the machine performances before each delivery. Jwell service engineers will always be here for anything you needed.

Usually it takes about 1 – 4 months depends on different machinery upon receipt of order advance payment.

Once clear your requirements and determined extrusion line is ideal for you. We will send technical solutions and Proforma Invoice to you. You can pay via TT bank transfer, LC as you like.

One. We provide both customized extrusion lines and technical solutions. Welcome contact with us for technical innovation or improvements for your future purchasing plan.

We produce more than 2000 advanced extrusion lines every year world wide.

We can send the small spare parts by air express for urgent matter. And the complete production line by sea to save the cost. You can either use your own assigned shipping agent or our cooperative forwarder. The nearest port is China Shanghai, Ningbo port, which is convenient for maritime transportation..

Yes, we support our business partners by pre-after sale service. Jwell has more than 300 technical testing engineers traveling world wide. Any cases would be responded with prompt solutions. We provide training, testing, operation and maintenance service for a life time.

Certificates

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: SGS

Extrusion Down Stream Equipment

2015-07-23 ~ 2020-07-23

Certified By: Other

Design, Development, Manufacture And Sales Of Intellectual Property Rights Management For Plastic Machine

2016-06-14 ~ 2019-06-13

Certified By: Other

Design, Development, Manufacture And Sales Of Plastic Pipe And Sheet Extrusion Production Line

2018-11-20 ~ 2021-11-19

Certified By: Quality Austria Training, Certification and Evaluation Ltd.

Plastic Extrusion Line

2010-01-29 ~